The world of PPE

EXPLANATION OF SAFETY STANDARDS FOR SAFETY FOOTWEAR

It's sometimes difficult to find your way around the SB, S1, S2 or S3 labels and additional requirements like CI, HI, HRO, etc. This Parade article will help you make sense of it all! Let’s start by looking at European certifications. We'll then take a look at the different standards for work and safety footwear, then talk about sole grip and finally explain the additional requirements.

Safety shoes and work shoes must meet requirements in terms of strength and durability, both for the materials that make up the shoe and for the shoe as a whole. Safety shoes and work shoes meet a large number of requirements in terms of upper materials, lining materials, sole materials, assembly strength, the ability to absorb perspiration, etc.

Work shoes and safety shoes are subject to European certification, from which European standards derive. By means of tests, these standards define the resistance requirements for shoes. These test methods are themselves standardised for the shoe resistance tests.

EUROPEAN CERTIFICATIONS

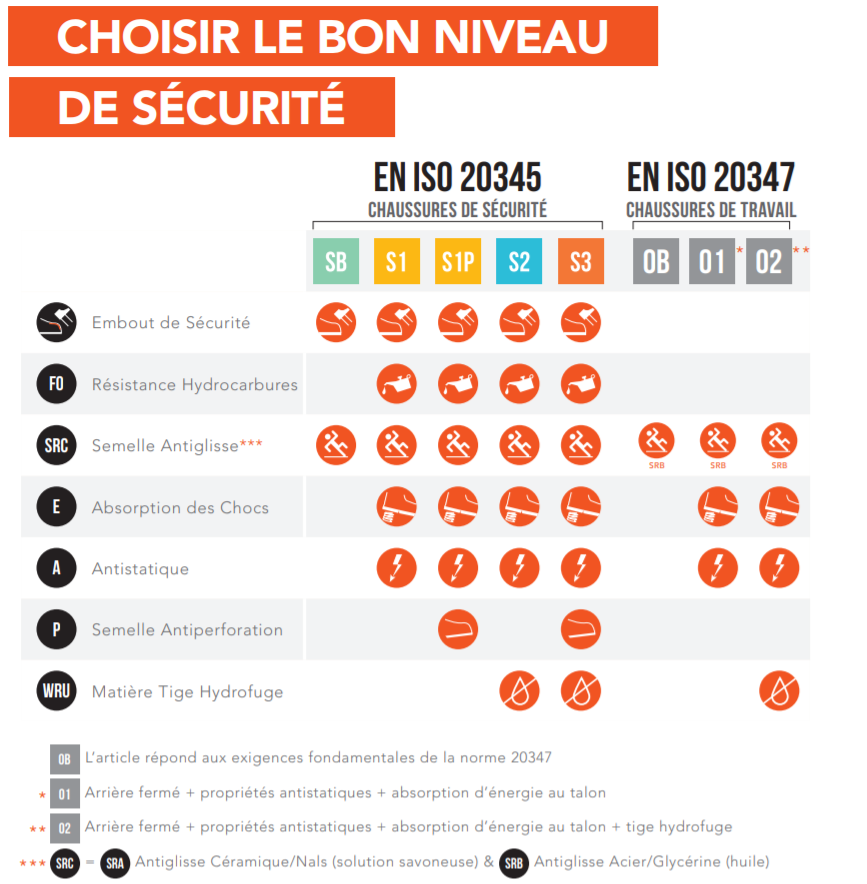

Shoes for professional use are subject to European certification. Standards are derived from this certification. Standard EN ISO 20345 defines the requirements for safety footwear. Standard EN ISO 20347 defines the requirements for work footwear. These standards are based on test standards (test methods) to check that footwear complies with the requirements.

EN ISO 20345 (safety footwear) differs from EN ISO 20347 (work footwear) in that it has a toe cap that protects the front of the foot and resists impact and crushing.

These two standards (EN ISO 20345 and EN ISO 20347) form the basis of the requirements for safety footwear and work footwear, but there are other, complementary standards to address specific risks.

Depending on the legislation in each country, the wearing of personal protective equipment (PPE) is regulated, or even compulsory, depending on the type of activity and risk.

EXPLANATION OF THE STANDARDS

Every level of shoe protection corresponds to the needs of the user, depending on the work environment. People are exposed to a variety of risk situations:

- Risks associated with user movements (falls, slips, etc.)

- Mechanical risks (cuts, rubbing, impact, puncture, crushing)

- Electrostatic risks (partially conductive footwear allowing static electricity to dissipate)

- Electrical risks (insulated footwear)

- Thermal risks (heat, cold, projection of molten metal, etc.)

- Chemical risks (corrosive and irritant liquids)

- Specific risks: hydrocarbon protection, ankle protection, chainsaw chains, etc.

1. Safety shoes

The first letter of the safety shoe label has the letter S. There are four label categories (SB, S1, S2, S3). Each label corresponds to a level of protection, from the lowest level SB (fundamental requirement) to the highest level S3.

SB

Numerous tests are carried out on the shoe's main components: upper, inner, sole, and on the assembled shoe. The tests assess tear resistance, wear resistance (abrasion), moisture absorption and desorption. For the sole: thickness, resistance to flexion, resistance to slipping. For the top of the shoe: impact- and crush-resistance of the toe caps.

SB footwear is safety footwear that provides basic protection, a safety toe cap and a slip-resistant sole. These safety shoes are suitable for a dry working environment and a flat floor.

Discover Parade’s range of SB label safety shoes

The following shoes fulfil the same requirements as SB shoes, with additional protection requirements.

S1

An S1 label shoe is a shoe that meets the same requirements as the SB shoe with additional requirements: closed back, antistatic properties, energy absorption at the heel, hydrocarbon resistance.

These safety shoes are suitable for a dry working environment.

Click to find Parade’s range of S1 label safety shoes

S1 P

An S1P shoe is a shoe that meets the same requirements as an S1 shoe, but with an additional requirement: an anti-puncture sole. These safety shoes are suitable for a dry working environment and where there is a risk of puncture through the sole (e.g. presence of sharp items)

To find our range of S1P safety shoes click here

S2

An S2 shoe is a shoe that meets the same requirements as an S1 shoe, with one additional requirement: a water-repellent upper (slows down the penetration of water into the shoe). Please note that S2 label shoes do not have puncture-resistant soles!

These safety shoes are suitable for wet working environments. Click here

S3

An S3 shoe is a shoe that meets the same requirements as an S2 shoe, but with an additional requirement: a puncture-resistant sole. S3 safety shoes offer the highest level of protection. The S3 level of protection can have additional requirements (for example CI: sole insulation against cold, see "additional requirements" section). So S3 label shoes combine all the features. These safety shoes are suitable for wet working environments and hazardous ground.

Find the full range of Parade S3 safety shoes, here.

2. Work shoes

(O), compliant with the standard EN ISO 20347, no toe cap required.

OB work shoes comply with the standard EN ISO 20347 and are suitable for a dry working environment and a flat floor. Take a look at Parade’s collection of work shoes that provide comfort and elegance in every situation. Click here.

To sum up:

SB = safety toe cap, non-slip sole

S1 = same as SB + closed back, antistatic properties, heel energy absorption, hydrocarbon resistance.

S1P = same as S1 + anti-puncture sole

S2 = same as S1 + water-repellent upper material

S3 = same as S2 + anti-puncture sole

OB = work shoe, without protective toe cap

SOLE SLIP RESISTANCE

Every shoe for professional use is subjected to a test relating to the sole’s resistance to slipping. This anti-slip requirement is symbolised by the SRA, SRB or SRC label.

SRA: the sole is suitable for soapy solutions on ceramic floors (tiles). SRB: the sole is suitable for greasy products (oil).

The SRC label combines the two requirements: SRC = SRA + SRB.

This label is added to the other shoe labels: OB, SB, S1, S1P, S2 and S3.

ADDITIONAL REQUIREMENTS

Each of the OB, SB, S1, S1P, S2 and S3 labels may be accompanied by additional requirements to provide additional protection (e.g. ankle protection, etc.).

- CI : insulates the foot from cold through the sole. Shoes subjected to a temperature of -17°C for 30 minutes. CI standard shoes are useful for working on cold floors.

- HI : insulates the foot from heat through the sole. Shoes subjected to a temperature of 150°C for 30 minutes.

- HRO : This describes the sole’s high resistance to heat degradation (resistant up to 300°C).

- FO : This label certifies the sole's resistance to contact with hydrocarbons.

- S : Energy-absorbing heel Heel cushioning for walking and stronger support (e.g. getting off a forklift truck)

- WRU (Water-repellent upper) : water-repellent upper that slows down water penetration

See our illustrated "HELP WITH YOUR CHOICE" chart to help you choose the shoe that's right for you!

Parade complies with these standards (EN ISO 20345 and EN ISO 20347), and obtains certification and authorisation to market safety footwear by carrying out mechanical and physical tests.

With over 40 years of expertise and R&D, Parade is doing everything it can to make its safety shoes more comfortable than ever. That's why, in addition to the standards described above, we have developed 3 exclusive technologies:

- VPS system upports the arch of the foot to reduce premature fatigue and provides unequalled comfort. This technology is ideal for people who work in prolonged standing positions

-Parade Air system : an air bubble in the sole that absorbs vibrations and micro-shocks. This technology offers very effective cushioning.

- DRS (delete resonance system) : dissipation of shock waves in the heel area

Related products

DISCOVER OUR NEWSLETTER

By entering your email address, you will receive our newsletter with our latest products, services, news and advice on prevention and safety.